info@qflexinc.com +1(714) 664-0101 1301 E. HUNTER AVE, SANTA ANA, CA 92705, USA

Aerospace

Following our motto- Extremely Difficult We Do all The Time, Impossible Just Takes a Little Longer- QFlex is a proud participant in many Aerospace and cutting edge technology projects.

MISSE project by NASA:

Nasa launched this payload to proof out many emerging technologies. QFlex added their proprietary heat sensing and other project. Read More

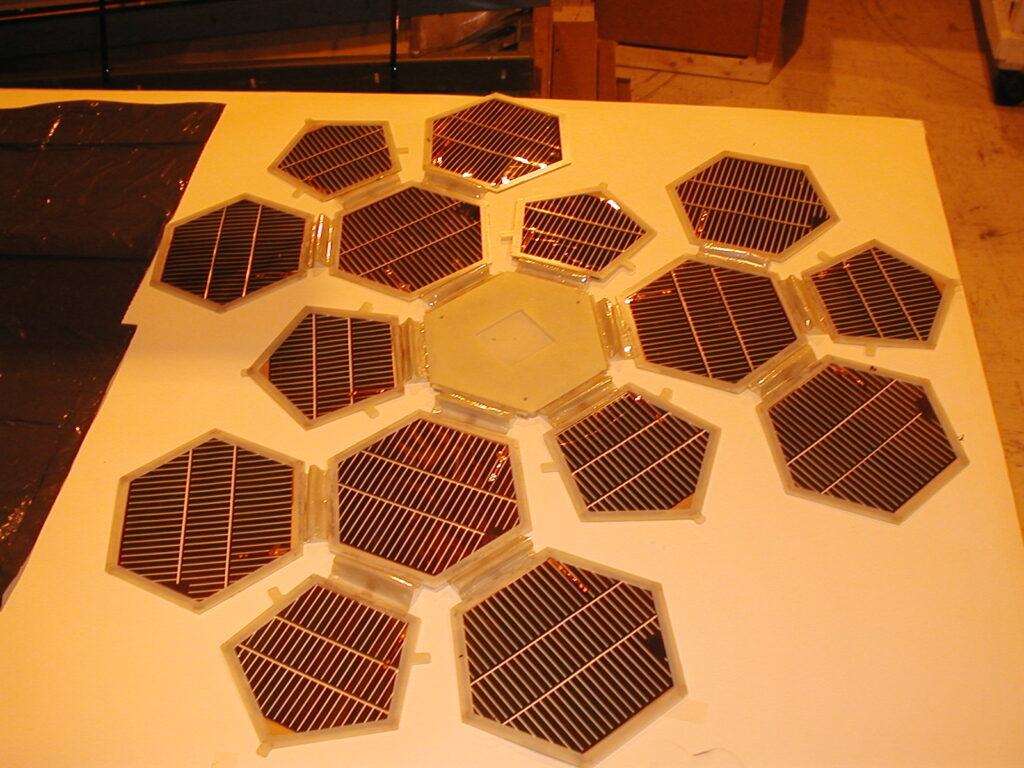

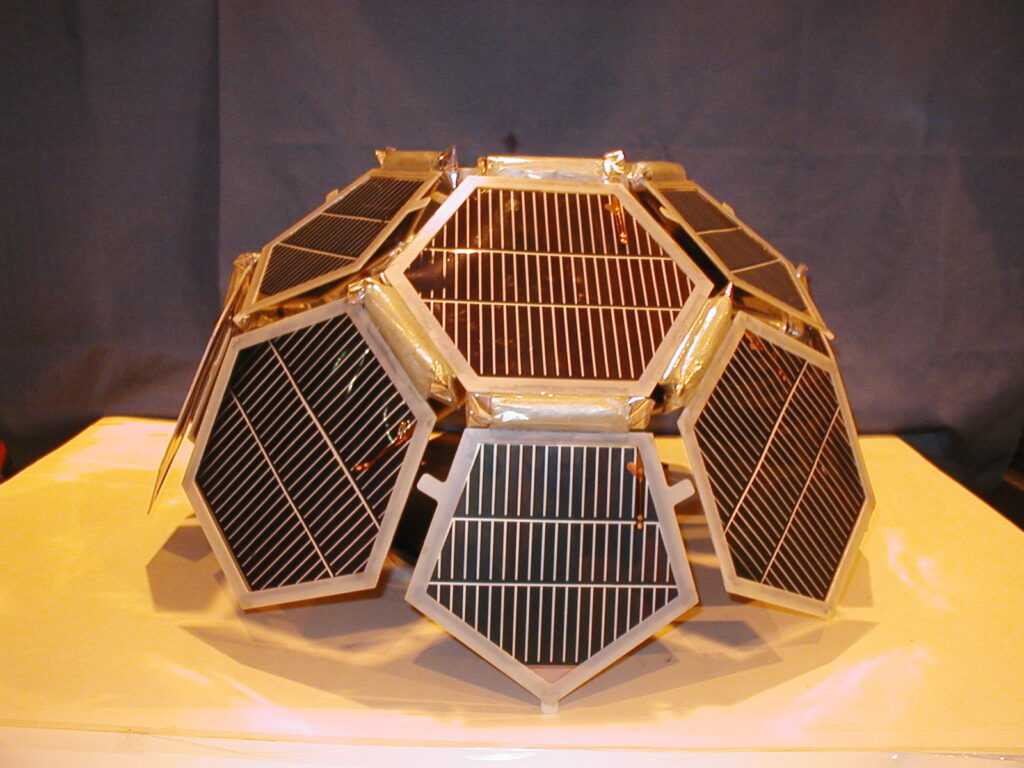

Powershpere:

This was a NASA project for micro satellites. The idea was to make a tightly packed solar cells package that would open up in a sphere in space. No matter what direction the satellite is turning, some solar cells would be exposed to sun and generate electricity to power the electronics.

SBIR- STTR:

These are specially funded projects run by various government agencies. QFlex won phase I for one SBIR and phase I for one STTR from Air Force research Lab (AFRL). Followed by successful completion of phase I, QFlex was awarded a much larger in scope phase II. Both these projects were completed successfully.

Shaped Wing Optimization:

This is an active SBIR program by NASA. Using QFelx proprietary technology, the wing shape will be optimized by setting up a process to identify the demarcation line where the laminar flow at leading edge becomes turbulent flow. The phase I is complete. The phase II has been awarded and scheduled to complete in June 2017.

HDI for MCM by Lockheed Martin. QFlex was awarded a major project by LMCO to create an interface between a multi chip module and other comm peripherals. QFlex designed and successfully manufactured a 88 layer (highest layer count ever made in flex industry) 3D – rigid flex. Qflex was given a performance award by LMCO for this project.

Tight From factor flex for satellite:

This was a University Research Center (URC) project. The challenge was to manufacture a very narrow but quite long flex that would be inserted in a sensor tube.