info@qflexinc.com +1(714) 664-0101 1301 E. HUNTER AVE, SANTA ANA, CA 92705, USA

Thermosense

Thermo Sensing Technology

InSitu – A Latin phrase which translates literally to ‘In position’.

QFlex, a California based technology company has developed the In Situ thermo sensing technology. It is highly accurate, very reliable and can be incorporated in products manufactured in high volume.

The system consist of a discrete layer of flex or a rigid PCB with pre designated copper pads where the temperature has to be measured. The traces connecting the copper pads can terminate at one of the edges of the layer or it can terminate to a section where the electronics for measurement will be located. If the traces are terminated for connection to slave electronics, any off the shelf connectors can be used. A simple modification of electronics can allow remote monitoring.

This is a ‘zero profile’ system. There are no components involved in the measurement area. All that is needed is to have a small copper pad in the designated area where the temperature will be measured.

The electronics used to measure the signal have been developed. We can give it to the customers or they can develop their own. We are in discussion with some customers to see if we can make an ASIC that will take care of signal processing. It is possible to convert this data to wireless signal on zigbee, wifi or ethernet for remote monitoring.

For further information, please contact :

Pete Uka

Director of Technology

QFlex Inc.

(714) 664-0101

pete@qflexinc.com

Background:

The process of measuring temperature is more than a century old. Various techniques have been developed and refined over a period of time. Some of these sensors are highly accurate like those used in deep space sensors. Some are very crude like the thermostat in a water heater.

Options to measure temperature.

1. Mercury bulb thermometer :

A small quantity of mercury (or alcohol for certain applications) is placed in a glass bulb with a long thin capillary tube marked with graduations to show temperature. This can be a highly accurate system if manufactured carefully.

Cons:

* The glass is very fragile and easy to break

* Mercury can be very toxic. A broken thermometer can spill mercury in uncontrollable ways and create a health and safety hazard.

* The reading is analog and it can be operator dependent.

2. Bi Metal unit:

Here, two strips of metals are welded on two ends. One has significantly higher expansion in heat. The strip with low expansion factor is heavy (thick) while the other one is thin and flexible. When exposed to heat, the thin strip expands and makes a bulge. This bulge can be measured using many techniques. These units are very sturdy, easy to manufacture, reliable and very inexpensive.

Cons:

The readings are not repeatable, the accuracy is low.

3. Use TCR of heater trace:

Here, the resistance of metal trace being used as a heater is used as a control parameter. Some metals have reasonable change in resistance with heat. During the heating process, the resistance of trace is continuously measured and used to turn the power on and off at a control temperature.

Cons:

* This is usable only for low cost, approximate temperature measurement. The control is not very fine and the temperature can have wide windows of variation.

* Many metals suitable for heating do not have good TCR delta for measurement.

4. IR measurement

Here the IR window mounted in a measurement unit measures the IR signature of the hot object and calculates the temperature on the surface. This technique allows remote, non contact measurement.

Cons:

* Has to be line of sight.

* Temperature reading cannot be used easily as a control signal.

* If the surface has some emmisivity, the readings will be less accurate. Best results are with a black matt finish.

* Presence of smoke or airborne particles may introduce error in measurement.

5. Pyrometer:

Pyrometer uses an optical window with a detector. The optical system focuses the thermal radiation on a detector. The output signal of the detector is related to thermal radiation (also called irradiance) by using the Stefen-Boltzman law that includes the emmisivity of the surface and Stefen-Boltzman constant. This is a non contact measurement system.

Cons:

similar to #4, IR measurement.

6. Semi conductor devices:

There are many devices available to measure temperature which have reasonably good accuracy and repeat ability. They are usually very inexpensive. One of the most common devices is a thermistor. Basically, it is a device with material that changes resistance with temperature. The curve to establish relationship of resistance / temperature is prepared and used to convert resistance values to temperature. Another such device is Resistance Temperature Detector (RTD)

Cons:

* While the devices are economical, the ultimate process to use them is not. In a circuit board, they will occupy valuable surface real estate.

* They have to be soldered on a surface of a probe which then is used to measure temperature.

* Since these are discrete devices, they have a profile over the probe surface, so they can not be used as a positive contact measurement device. At best, the device must be in close proximity of the hot surface so there may be some loss in accuracy of measurement.

* If the measurement range has wide fluctuations, the solder joint (used to install the device) will have thermal expansion / contraction cycles. Ultimately, this will cause a solder fatigue and create microcracks in the solder joints. This in turn causes intermittent measurement and ultimate failure.

7. Thermocouples:

One of the most common methods is to use thermocouple (T/C) technique. In this process, two dissimilar wires are welded together to make a ball joint. Each wire is made from specific metals. If a copper wire is welded to Constantan wire, it makes a junction called Type T, if a Chromium with 10% nickel wire is welded to Aluminum silicon with 5% Nickel wire, it is Type K etc. When this junction is heated, there is a low level voltage proportional to temperature that can be measured and converted to a meaningful reading. None of these temperature/voltage curves are linear and a polynomial equation is used to calculate actual temperature.

Cons:

* In order to make this work, the junction cannot have a third metal, it is a bi-metal junction only, so it can not be soldered or welded using a welding rod. It has to be made by TIG , define welding – by fusing the two metals together. This is an operator dependent process. If not done correctly, it is easy to produce unreliable joint.

* While the wires can be insulated, the joint itself is open. If the environment is corrosive (gaseous) or chemicals are involved, this open joint will not work. By using various special processes, the joint can be insulated, but it is expensive, difficult to do, easy to break down, unreliable and not durable. It also reduces the response time.

* By the very nature of the welding procedure, it is not possible to automate the process. This means no part to part consistency and no high volume process. This is strictly a manual, or at most, semi automated process.

* The welding process creates a relatively large mass. A large thermal mass takes time to heat up so the response is not adequate in most processes.

* Over a period of time, due to expansion/contraction cycles, this joint can break down.

The ball joint is a relatively large mass connected to a thinner wire, any relative flexing of thejoint can easily break the wire connection to the joint.

* Sometimes, the two wires are just twisted to make a connection. This is a highly unreliable connection.

* Wires can crack if not handled carefully.

* Special connectors with two matching dissimilar metals are needed to connect to a measurement device.

In Situ Thermo Sensing Technology (ThermosenseTM) by QFlex Inc.

What is In Situ Thermal sensing?

Basically, In Situ Thermal sensing is an element on a circuit board (flexible or rigid). It can be part of any existing design or be a discrete element by itself. The designated points where a temperature is to be measured is called a ‘node’ – a copper pad. A trace (called ‘common’) on the top layer (for single layer construction) or on a sub layer (for multilayer design) connects to each node in series and extends to one designated measuring area. From each node, a second trace (called ‘node trace’) extends to the measuring area. The connection is done by conventional copper plating processes (for multilayer design) that are field proven and highly reliable. When the nodes are exposed to temperatures, there will be a proportional measurable analog signal between common and each node traces. Electronics in the measurement area are set up to scan each combination.

If so desired, this technique can be an integral part of a multilayer PCB where it is necessary to measure temperatures in certain areas, e.g. under components that may overheat or sections of board that may be exposed to high temperature environment. All that is needed on the outer layer(s) of the PCB is a small copper pad (can be under a component). This copper pad is connected by plated through via to a sub layer where the connecting traces take the signal to the processing electronics.

Since this is a zero profile system, it can be used under pressure (e.g. measuring temperature while the parts are under pressure).

The data can be :

1. Stored on board for later retrieval.

2. Transmitted to other devices (or a PC) by wire or wireless.

3. Used to trip a relay (to trigger shut down due to over heating).

4. Used to control a function, such as reducing brightness in a mobile device when the battery overheats.

5. Displayed as multicolor LEDs to show level of temperature

6. Displayed on LCD/LED screen

6. An audible signal to alert high temperatures.

7. Used to control temperature control circuitry.

Applications:

In Situ Thermal sensing is a generic technology with wide open applications. The salient features of this technology are already being used by Tier 1 customers.

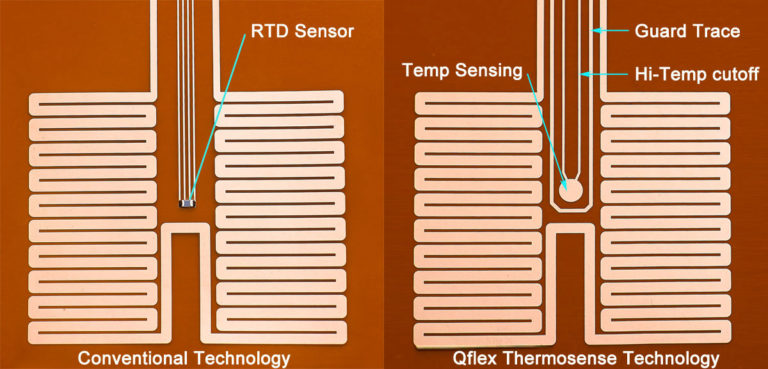

Heater + Measurement for precise temperature control :

A flexible or rigid board can be used as a heater by creating a serpentine pattern of a metal trace with a specific resistance. In order to control the temperature, it is necessary to give a continuous signal to the power controller so that the surface temperature is maintained within specified limits. While the planar heaters work very well due to their form factor, there is no standard technology

to set up sensing with zero profile. This technology offers a built in sensing or a discrete part that is laminated to the heater surface without changing the form factor. It is easy to have two sensing areas as a redundancy for high temperature cut off. It is also possible to measure temperature in many locations on a heater and calculate average temperature and use that as a control signal. Of course, real time data collection is always there for all these locations.

Temperature sensors for harsh / severe environment:

The element will be a flex cable made using conventional printed circuit board processes. The cable will be of suitable length and shape to fit in allowable mechanical constraints. A ‘node’ is located on the cable so that it is in close proximity or in actual physical contact with the area to be measured. This cable is either plugged intoa hand held device or signal output is processed using custom electronics. Since there is no component on the sensing surface, norelief (cavity) is necessary in the contact area.

Harsh Environment/Chemical Exposure:

The PWB or flex cable is suitably coated with appropriate layer to protect against corrosive environment or chemicals. If the environment is one which will attack copper, the copper pad can be coated with other metals like silver, gold, tin, nickel or Rhodium. If all these metals are susceptible to the chemicals involved, it is easy to use any suitable polymer coating over the copper pad. For high temperatures, ceramic base and ceramic coatings are used.

Predicting Failure in PCBs.

In most electronic circuits, most common mode of failure is heat related. High temperature incursions are hard to anticipate, measure in real time, and take preventive actions.

When an electronic system board is under power and continuously used over a period of time, the components in various locations start heating up. In Situ design can give actual temperatures in real time for all specific locations with complete history over a period time.

Measuring Temperature under pressure (Hydraulic or IsoStatic)

If this is needed, the In Situ system can provide highly accurate data. Many conventional measurement systems can not survive direct (hydraulic) or isostatic pressures.

How it is done:

Basically, the conductive layer on top in a flex or a rigid acts as a temperature sensing plane. Temp. sensing ‘zones’ are assigned and located based on needs. For example: if there is a memory chip that can get overheated, a zone directly under the chip is allocated a channel number. Same for processors, power transistors etc. All that is needed to measure is a via pad at the designated location. Except for the via pad, the balance of the real estate on the board is used like any other PWB.

The designated via pads are connected to a trace at one of the sub level (e.g. at layer #2, #3 etc). There is a common trace running in series connecting each location (node). Then a separate trace is routed to each node. Now we have a common trace and one trace per measurement point. By measuring the signal between each trace and common trace, temperature is measured for that location by scanning the signal for each combination. This data can drive green/yellow/red LEDs (to indicate level of heat rise), audible alarms, real time data collection or all of the above.

Since this circuitry takes up only a small part of the top layer, the balance of the real estate is used for typical PWB use. All components are placed by same process, the signals are routed the same way, no special processes are necessary. The process windows for PWB manufacturing and assembly are unchanged and all typical raw materials used in PWBs are unchanged. The analog signals from multiple points being measured needs to be processed as per the requirement.

This is very important for high reliability systems like high end servers, telecom, military systems etc. Let us say the data shows a processor is heating up. The typical heat rise is from room temp. to 170 deg. F. Let us say there are 5 processors on board. During ‘burn in’ test, all that the test can tell you is that all processors worked. With this design, it is possible to know if one processor is heating up faster than the other ones and which one will fail first!

In real world use, the customer will know if a specific processor or a memory chip is slowly over heating. Not only they will know approximately how long it will go on before failure (from past history), they will know which specific component on the board will fail. That allows quick replacement and very low down time. Using the previous example, if the processor has been historically at 140 deg. max and all of a sudden the temp is rising to 150 or 160, then the system can be scheduled to shut down by plan rather than by an eby an emergency procedure..

The In Situ approach allows evaluations of various designs in order to pick the most robust one. The thermal design of the whole system can be optimized based on the real data over the whole board. By taking care of the most vulnerable zones, the MTBF for the system can be increased significantly.

A Revolutionary Tool to Create a Thermal Profile of a Reflow Oven.

Typical automated PWB assembly process involves solder paste screening, automatic pick and place, followed by reflow in a conveyorized chamber. Conventional tin/lead (60/40) solder reflows at 360-375 deg F (182-190 deg C). Lead free solder melts at much higher temperature.

Reflow chambers transfer heat by convection, by infra red process or combination of both. Both of these processes heat up the entire PWB including the components. If the temperature at the solder paste level is too low, the solder paste will be only partially melted creating grainy solder which will trap flux inside. This flux can corrode the solder joint over a period of time and create intermittent failure. The grainy solder will not give the best possible connection and structural integrity can be compromised. If the temperature is too high, valuable components and/or base PWB including plated through holes (due to Z axis expansion) can be damaged. High temperatures will reduce the viscosity of solder and the process can cause solder bridges between adjacent pads in high density designs. Each solder paste manufacturer has its recommended thermal profile curve for the best performance of solder paste.

The worst failures occur at the solder joints. If a solder joint is cracked, it will cause intermittent failures. Since these failures cannot be duplicated under controlled environment, troubleshooting becomes extremely difficult.

Another failure mode is at the component level. While Hi Reliability boards do go through ‘burn in’ process, it is a static test and no real time data can be collected to see the temperature performance of the active components during use.

Any marginal assembly process deviations that might cause future solder joint failures are hard to pin down. This problem has been aggravated because of the lead free soldering which has a tighter process window. Any failure analysis on returned part is difficult because no real time data during use is available.

It is therefore of utmost importance to accurately determine the thermal profile of a reflow chamber. While the required profile curve is readily available, measuring ACTUAL temperature of the pad on a PWB during reflow is not easy. It is not possible to find out if the process matches the required reflow profile curve including the heat rise and crucial melting point/time duration part of the curve.

Various thermal profiling systems are on the market. Most of them use discrete thermocouple wires. These wires are attached to a data collection system with wires or by wireless. The wires are attached to selected locations and it is assumed that the temperature readings reflect the actual reflow process of the solder paste. Of course, this is not true. Measuring the temperature near a component in the air and/or away from actual solder paste pad simply will not profile the reflow process accurately.

In Situ Process for Solder reflow Chamber:

The system consists of a multilayer polyimide board with plated though holes (PTH). The PTH connect the inside signal traces to copper pads on top layer. There is a section on the PWB with necessary electronics to collect data. A cap with thermal insulation to protect the electronics from heat in included.. This PWB is run through the chamber with process setting. The copper pads are exposed to heat just like actual PWB with solder paste. The temperature rise on the copper pad is measured very accurately (0.1 deg C) and instantly (0.1 sec.). There are no components on the copper pad or under the pad ( internal layers). Nothing is soldered over the pad (thermister or temperature sensing RTD). There is nothing extraneous anywhere in the sensing area. This now gives the true measure of the actual temperature of the PWB solder pads. The temperature of the copper pads on the system is measured under the dome in the electronic section and the data is transmitted wirelessly to a laptop in real time. As an option, data can be stored on board and downloaded to a PC later on. Since the temperature sensing is done on a real multilayer PWB at the top layer copper pads, all the uncertainty is removed from the measurements.