info@qflexinc.com +1(714) 664-0101 1301 E. HUNTER AVE, SANTA ANA, CA 92705, USA

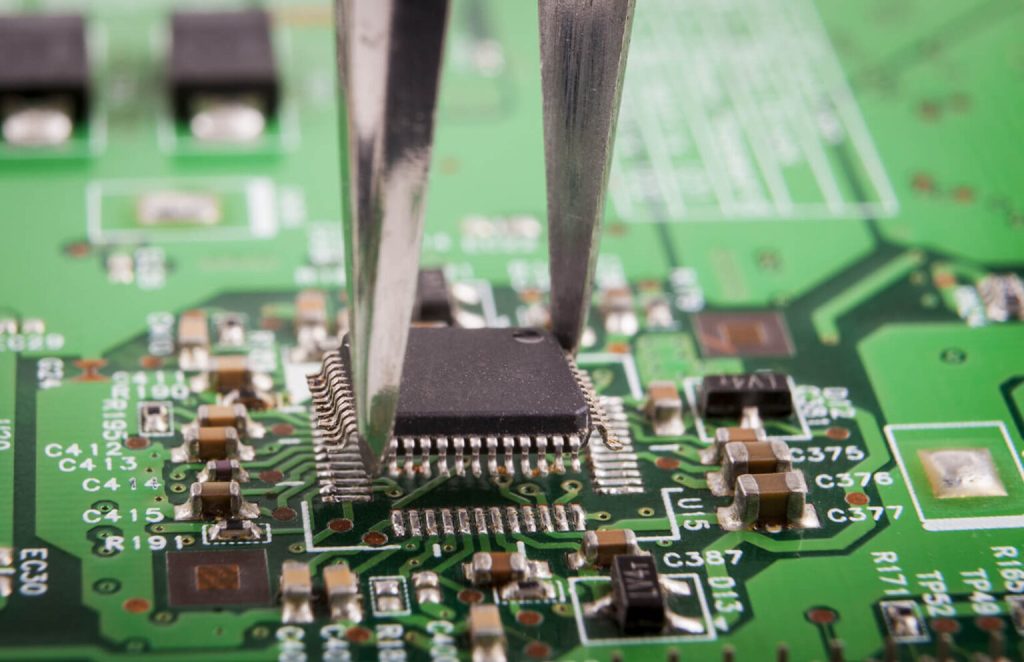

Expert Component Assembly Services

“At Q-flex Inc, we specialize in providing high-quality circuit board assembly (CBA) services for a wide range of industries. From prototype runs to high-volume production, our expert engineers and technicians ensure that every board is assembled with precision and meets the highest industry standards.”

- Mission Statement:

“Our mission is to empower innovators by delivering reliable, cost-effective, and timely PCB assembly services, allowing you to bring your products to market faster with confidence.” - Here is some more information about Q-Flex Inc assembly services:

- Why Choose Us?

- Expertise: “With over 10 years of experience in PCB assembly, we have the technical knowledge and industry experience to handle even the most complex designs.”

- State-of-the-Art Equipment: “We use the latest assembly machines and technologies, ensuring the highest quality and efficiency.”

- Full-Service Support: “From component sourcing to final testing, we offer a complete end-to-end PCB assembly solution.”

- Fast Turnaround: “Our fast-track services ensure that even tight deadlines are met without compromising quality.”

- Cost-Effective: “We provide affordable pricing options without sacrificing performance, quality, or customer service.”

Our Circuit Board Assembly Services:

- PCB Assembly (SMT & THT)

“We provide both Surface Mount Technology (SMT) and Through-Hole Technology (THT) assembly for a variety of PCB designs. Whether you’re working with a high-density design or need components that require manual assembly, we have the equipment and expertise to get the job done.” - Prototyping & Low-Volume Production

“Need to test your design before going into mass production? We offer rapid prototyping and low-volume PCB assembly services to help you validate your designs, all while keeping costs under control.” - Component Sourcing

“We work closely with trusted suppliers to source the highest quality components at the best prices. Let us handle the logistics, so you can focus on design and development.” - PCB Testing & Quality Assurance

“Each board undergoes thorough testing, including Automated Optical Inspection (AOI), X-Ray Inspection, and Functional Testing to ensure that every PCB is free from defects and works as expected.” - Rework & Repair Services

“If your PCB assembly has a defect or needs modification, our rework and repair services can fix and bring your board back to working condition quickly.” - Assembly for Complex Boards

“From multi-layered PCBs to flexible circuits and high-frequency designs, we specialize in assembling complex boards for industries that demand the highest standards.” - Full Turnkey Solutions

“We offer a full turnkey solution, handling everything from the design files and components to assembly and final testing. We’ll manage your entire PCB assembly process from start to finish.”

Industries We Serve:

- Consumer Electronics: “PCB assembly for smartphones, tablets, wearables, and home electronics.”

- Automotive: “Reliable assembly for automotive control systems, sensors, and infotainment systems.”

- Medical Devices: “High-precision assemblies for medical devices that meet rigorous standards.”

- Industrial Electronics: “PCB assemblies for control systems, robotics, and other industrial applications.”

- Aerospace & Defense: “Advanced PCB assemblies for aerospace and defense equipment, ensuring reliability and performance in critical applications.”

Our PCB Assembly Process:

- Design Review & DFM Analysis:

“Before we start assembly, we conduct a detailed Design for Manufacturability (DFM) analysis to identify any potential issues with the design and ensure it can be easily assembled.” - Component Sourcing:

“Once your design is finalized, we source the necessary components, ensuring they meet the required specifications and standards.” - Assembly & Soldering:

“We use both SMT (Surface Mount Technology) and THT (Through-Hole Technology) techniques, depending on your PCB’s requirements, to precisely place and solder each component.” - Testing & Inspection:

“Your PCBs undergo rigorous testing to ensure they meet functional requirements, including Automated Optical Inspection (AOI), X-Ray Inspection, and Functional Testing.” - Final Quality Check:

“We conduct a final inspection of the assembled boards to ensure everything is in place and fully operational.” - Packaging & Shipping:

“Once approved, your PCBs are carefully packaged and shipped to you, ready for integration into your final product.”

Quality Assurance:

- Certifications:

“We are ISO 9001:2015 certified, ensuring that all our processes meet global standards for quality and consistency in every PCB assembly project.” - Process Control & Testing:

“Our quality control process includes stringent inspection and testing at each stage of the assembly process. We ensure that each PCB is fully functional and free from defects.” - Traceability:

“Every PCB assembly project is traceable from start to finish. You’ll have access to detailed reports on components used, assembly procedures, and testing results.”